4-Bar Odometry Pod (32mm Wheel)

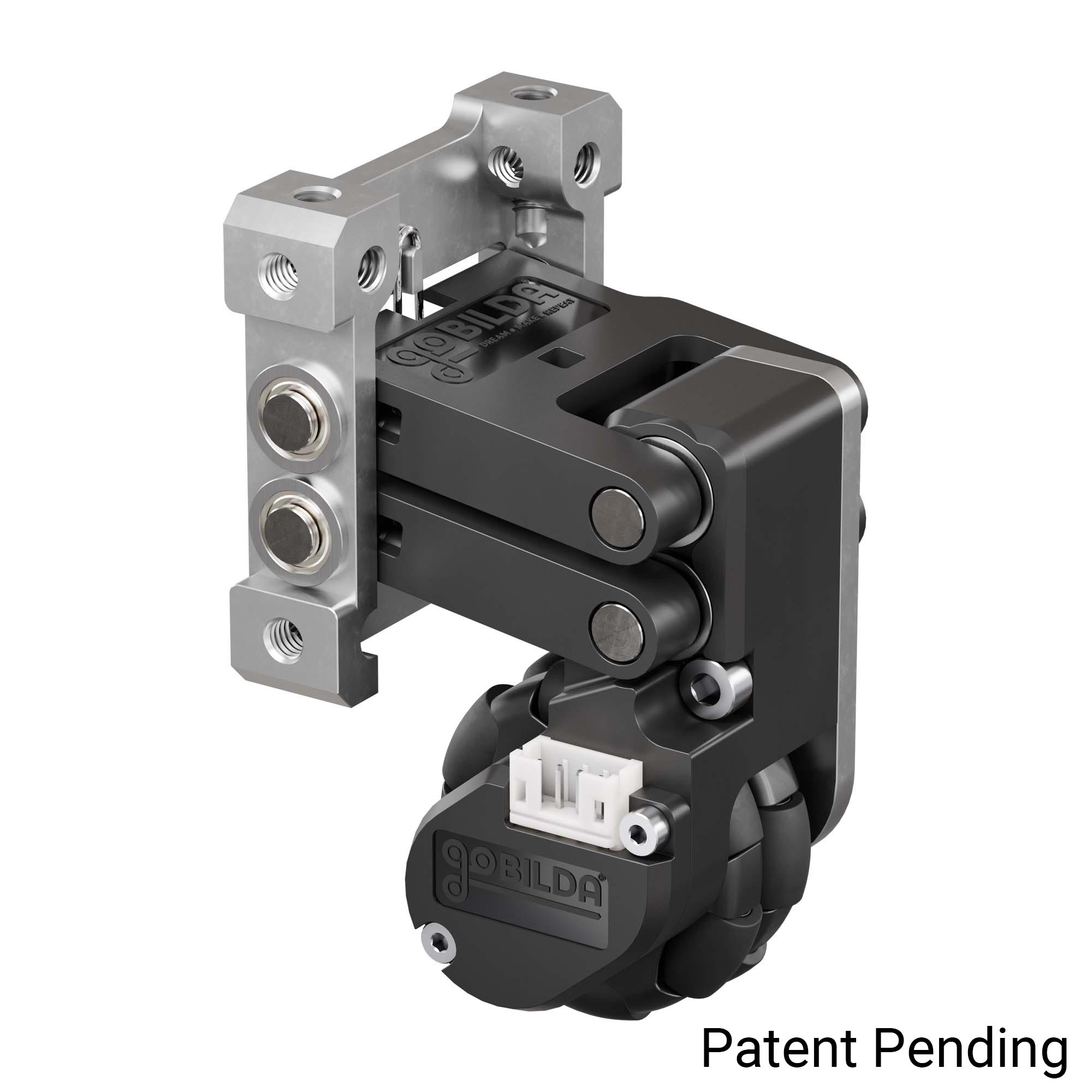

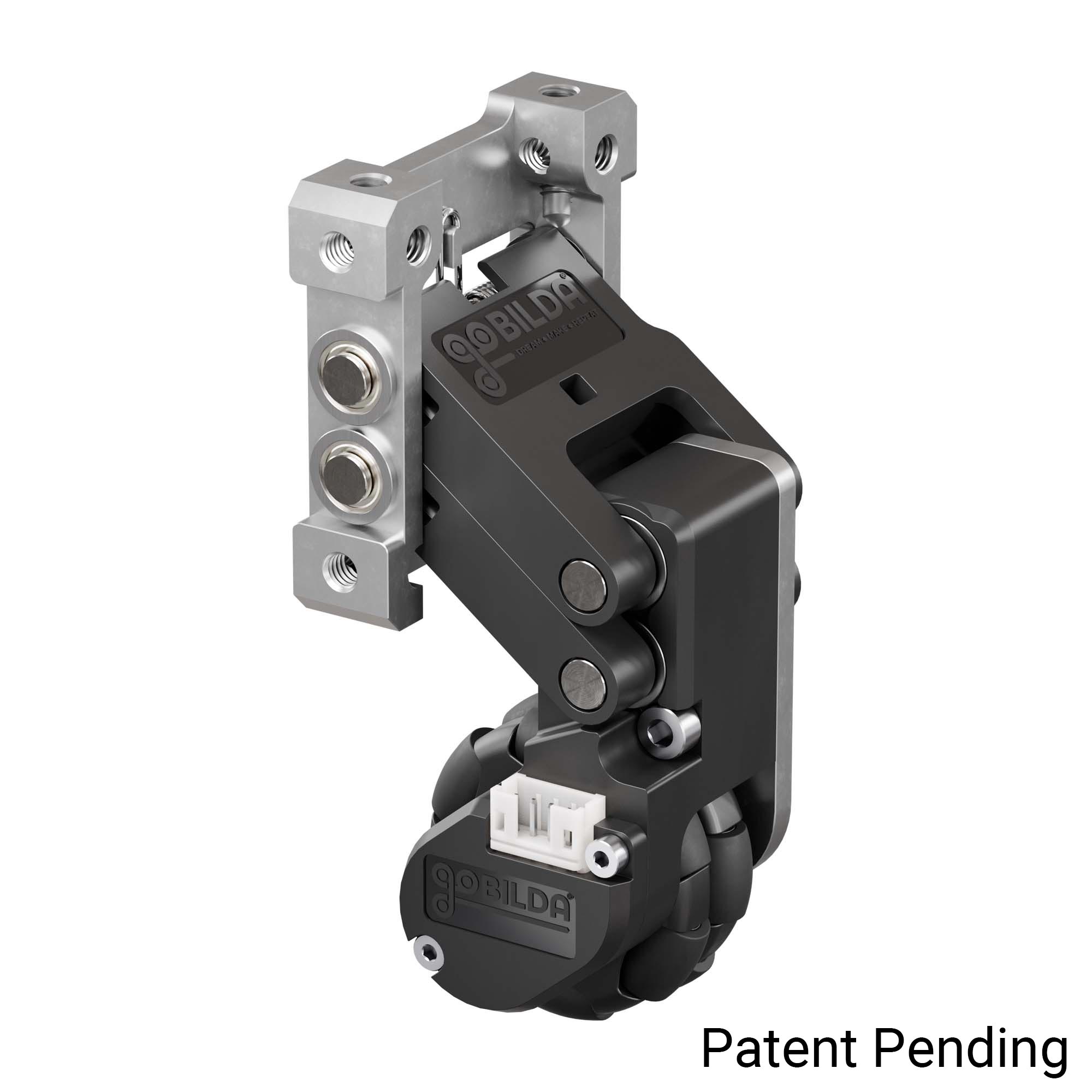

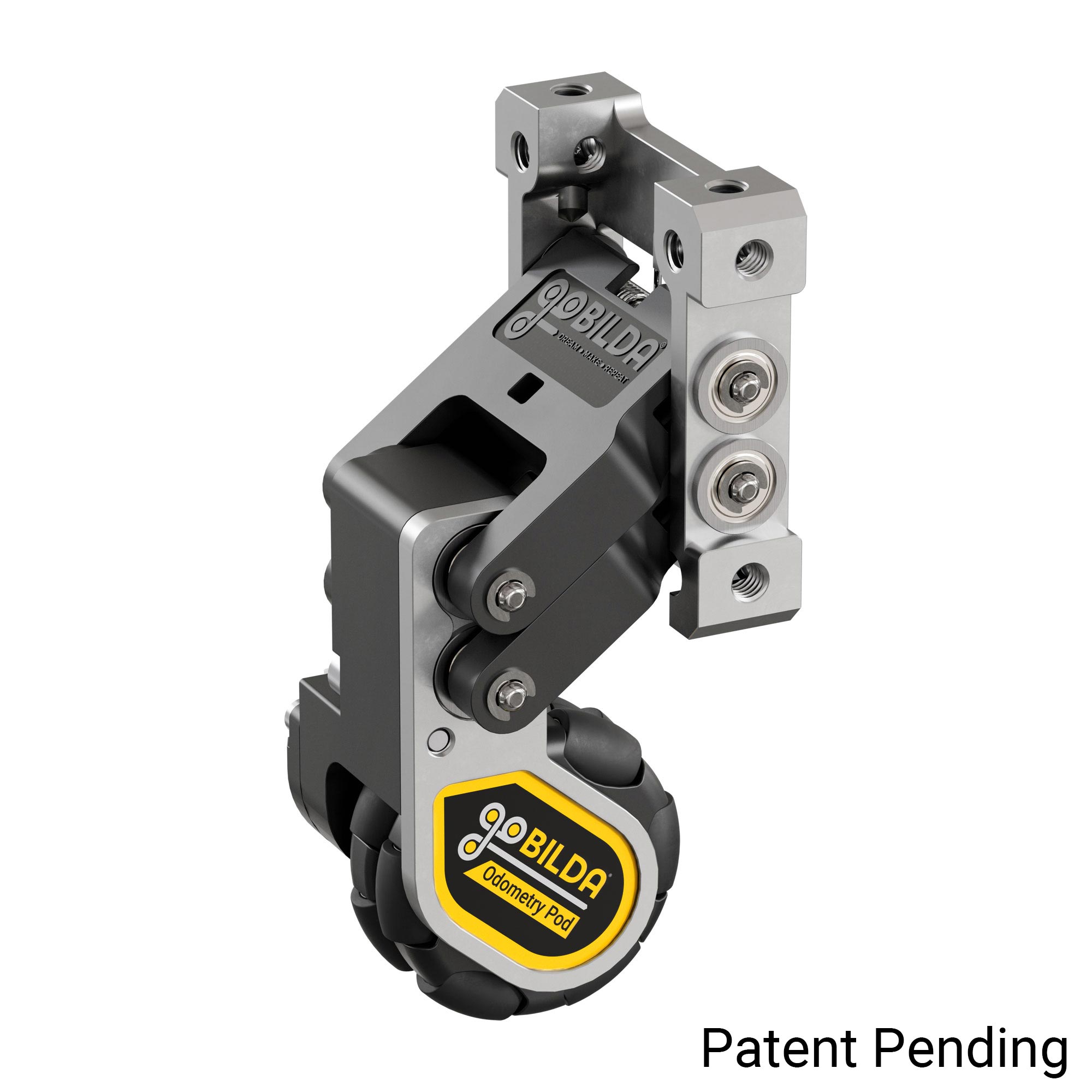

SKU:Help your robot find its way with the goBILDA® 4-Bar Odometry Pod! It’s a precisely-designed sensor that ups the accuracy of localization when your robot operates autonomously. This 4-Bar Odometry Pod provides maximum mechanical ingenuity while saving you real estate in your robot.

Designed from the heft of FTC experience in the goBILDA® R&D team, this Odometry Pod innovates to a higher level than comparable alternatives. The 4-Bar Odometry Pod:

- Uses clever internal packaging in place of the gears often seen in odometry systems and encoders, resulting in smoother rotation and eliminating the possibility of backlash.

- Comes with all the supporting components required to attach the pod to your robot.

- Arrives with the pod itself fully assembled so that you can focus on the code and implementation that’ll ace your autonomous operations.

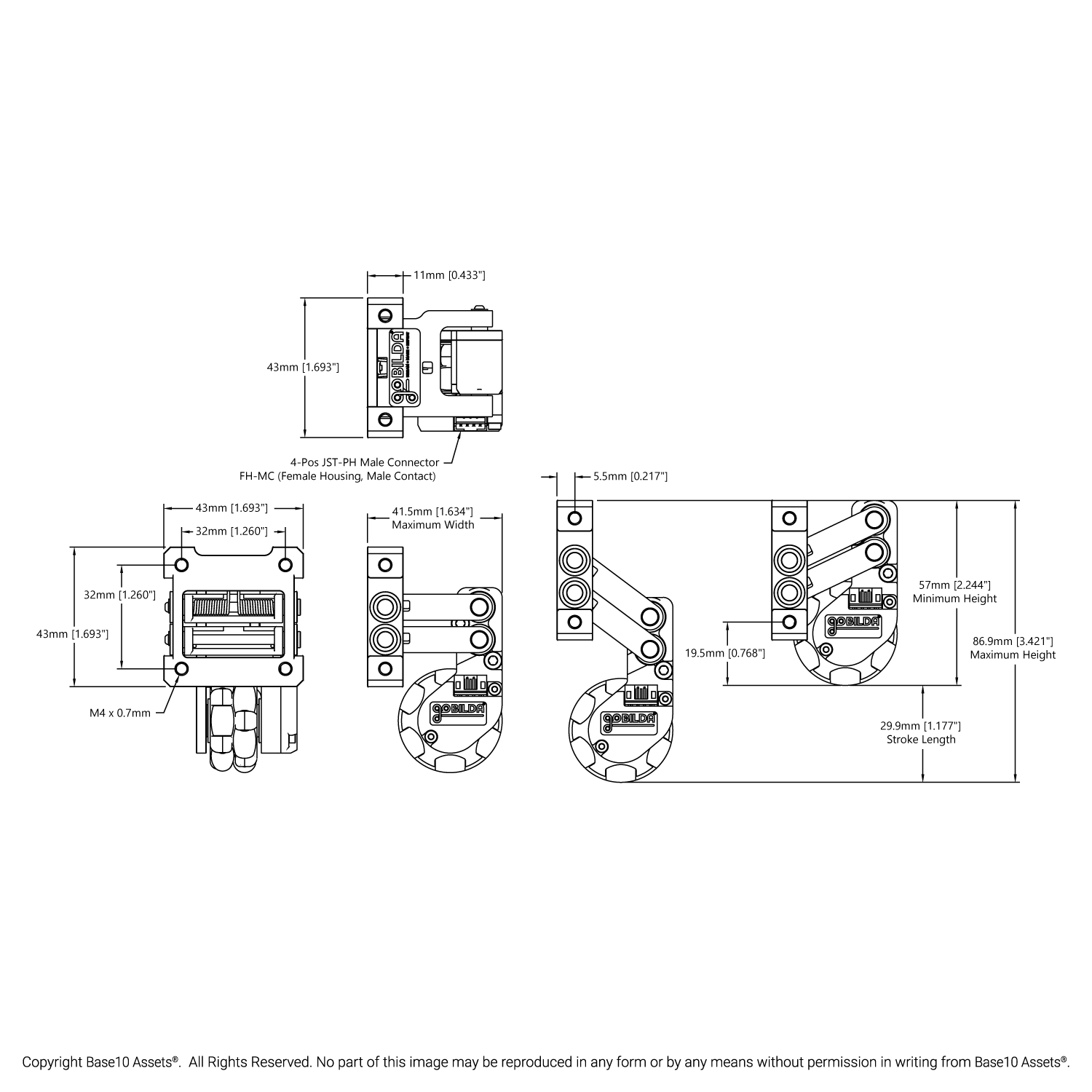

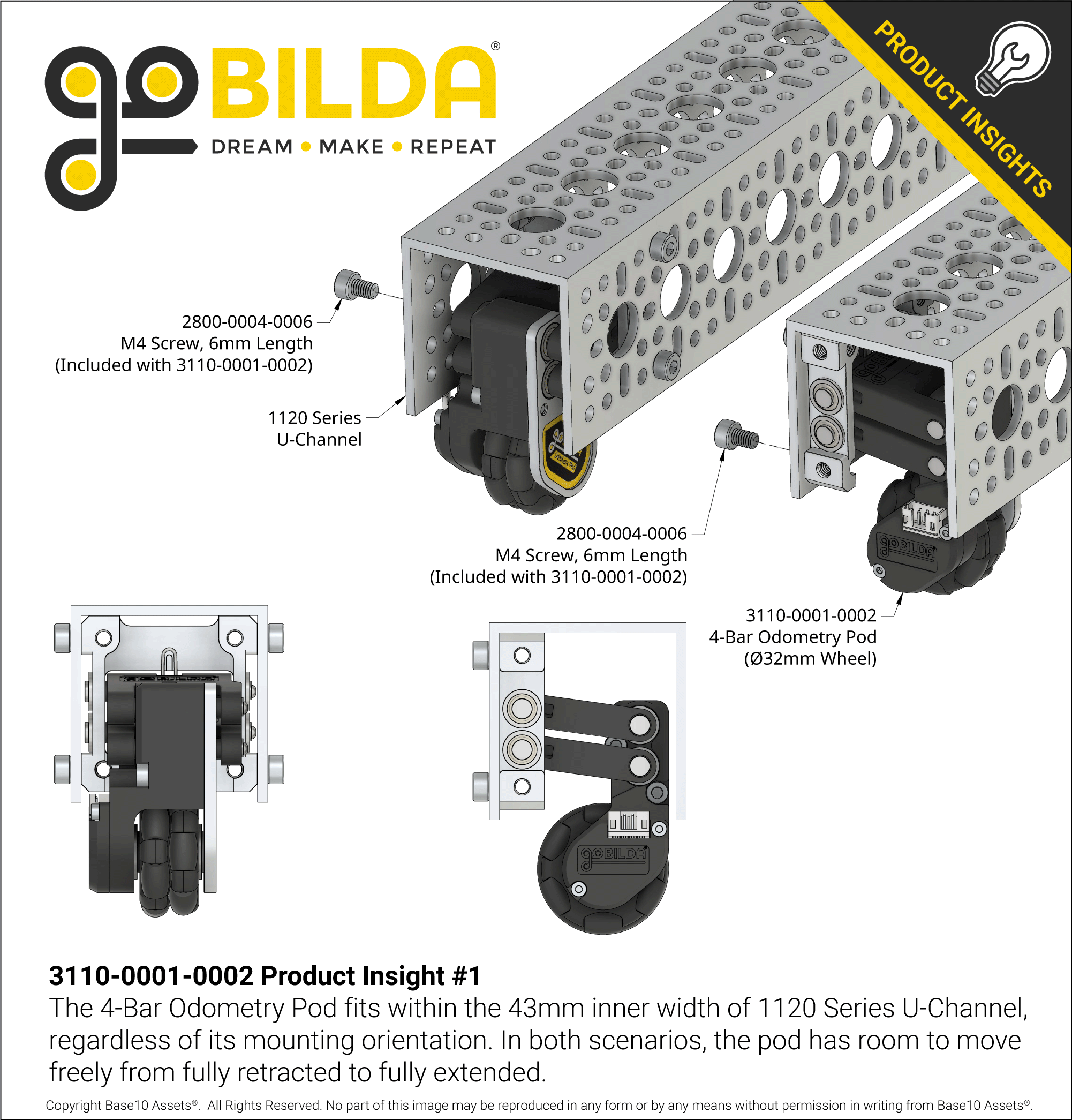

- Is designed to fit within a 43mm x 43mm profile for easy integration with 1120 Series U-Channel.

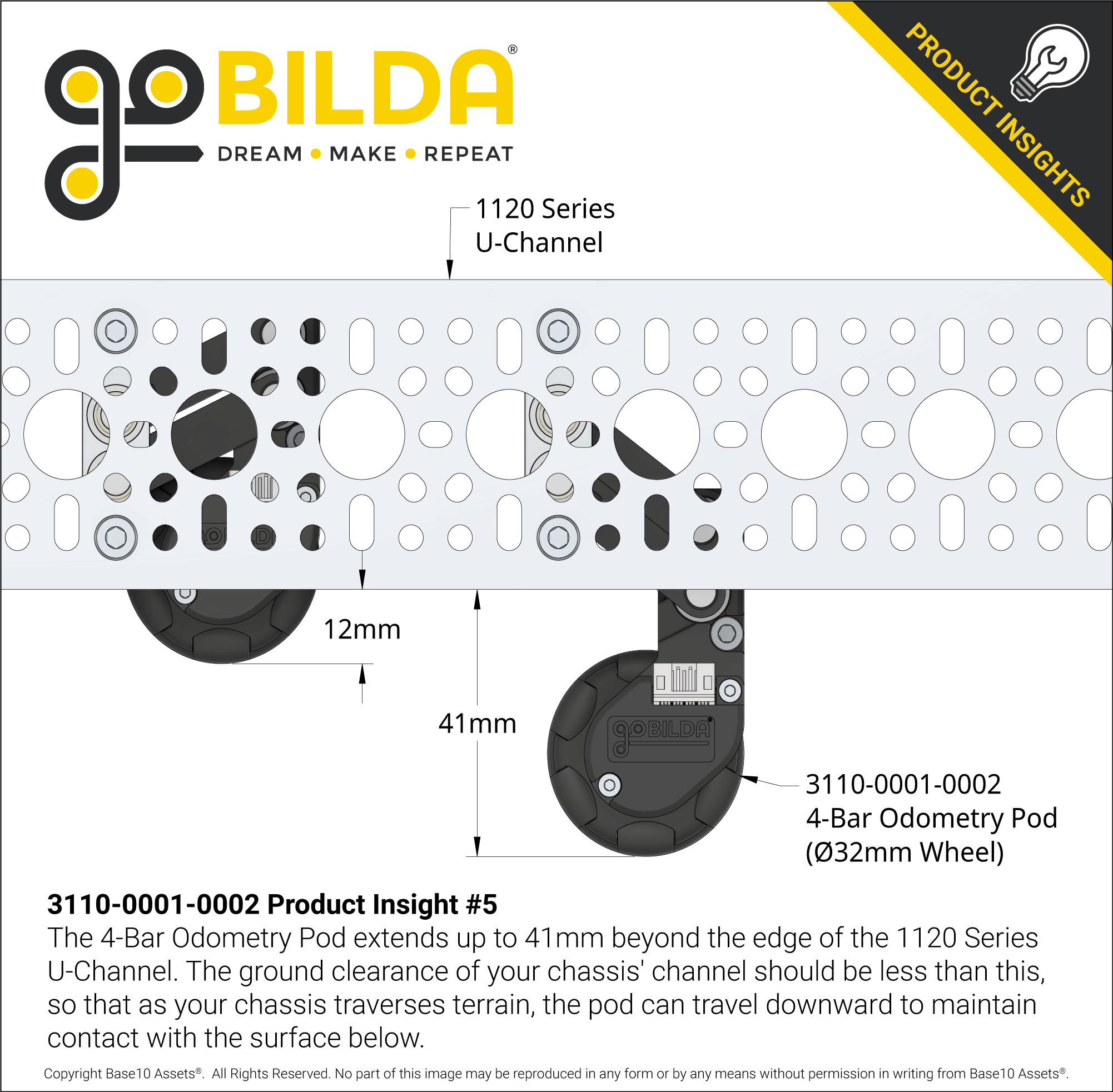

- Has a 32mm diameter wheel that excellently fits within channel, rotates under your chassis, and overcomes small obstacles—and paired with the 2000 PPR encoder, the wheel delivers enough data to be incredibly precise, while not sending so much that your controller risks missing steps.

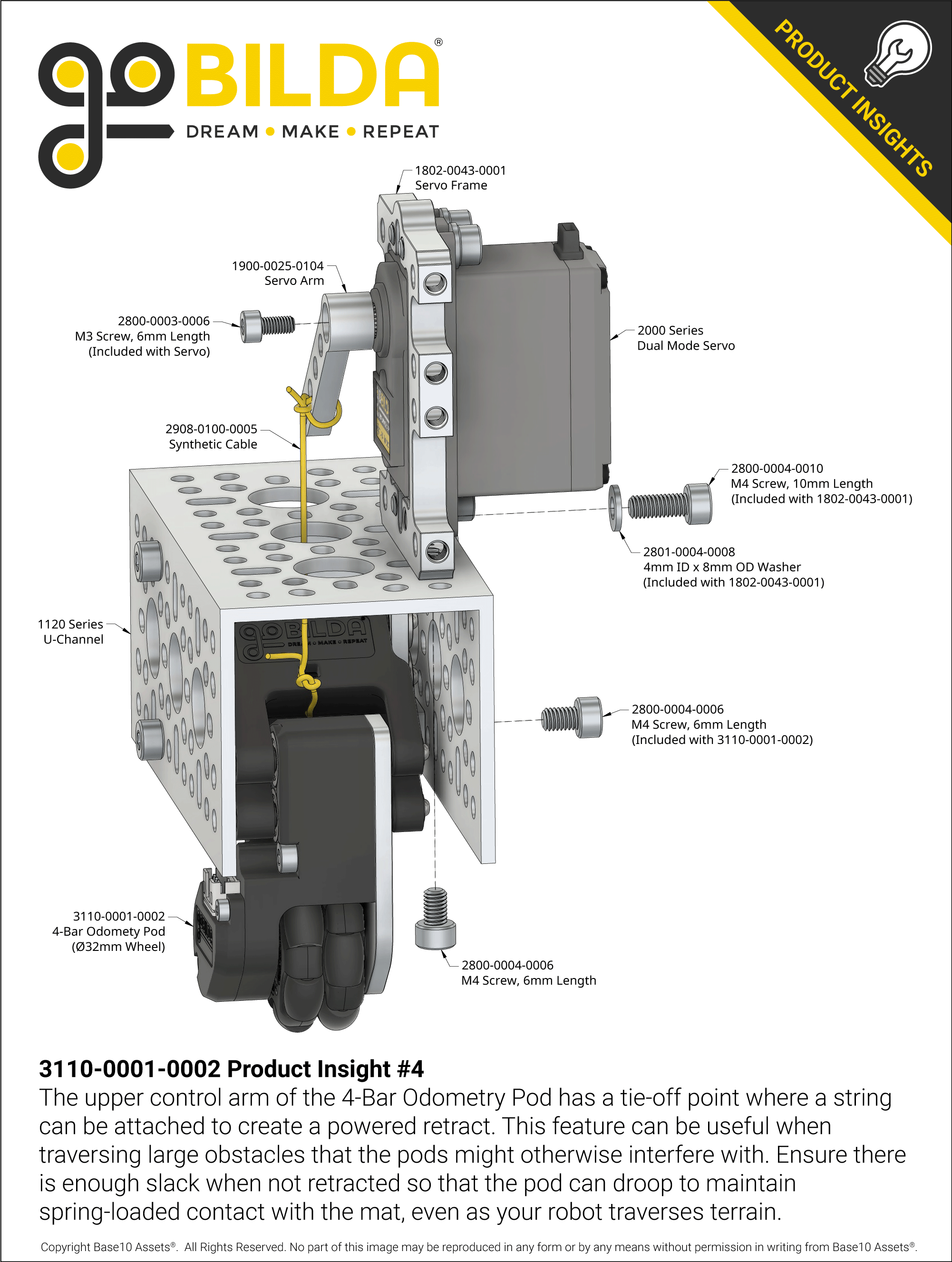

- Boasts a torsion spring that provides a consistent, nearly linear downforce for the entire stroke of travel.

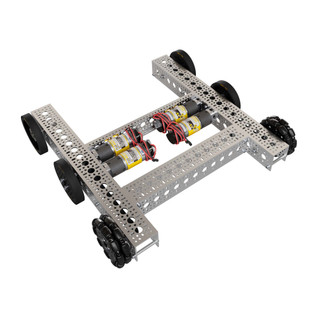

The Product Insights show the recommended mounting location for a chassis that is as out-of-the-box as this pod. If your chassis has been changed according to your innovative and/or unorthodox implementation, you may need to adjust your mounting to ensure accurate tracking.

Tuned for FTC

This pod was designed with FIRST Tech Challenge (FTC) teams, chassis, and—of course—FTC fields in mind. The wheel pairs perfectly with the soft tiles that teams must drive on. It can be used on other surfaces, but we recommend verifying its effectiveness before implementing it in operations beyond FTC fields. And on the electrical side of the robot, the 4-Bar Odometry Pod is perfectly compatible with the REV Control Hub used in FTC.

What is Odometry?

We humans have many ways to find ourselves and discover our paths in life. For robots, odometry is the answer. Odometry describes calculations and solutions that help your robot know its location from its travel data in a process called “localization.” Localization is crucial to autonomous operation.

The Power of the Pod

This odometry pod provides precision localization. Unlike encoder-equipped drive motors, whose rotation data doesn’t always reflect the actual motion of a chassis (see the "Why Odometry Pods?" box below), this odometry-dedicated solution is designed to reliably track the position of the chassis.

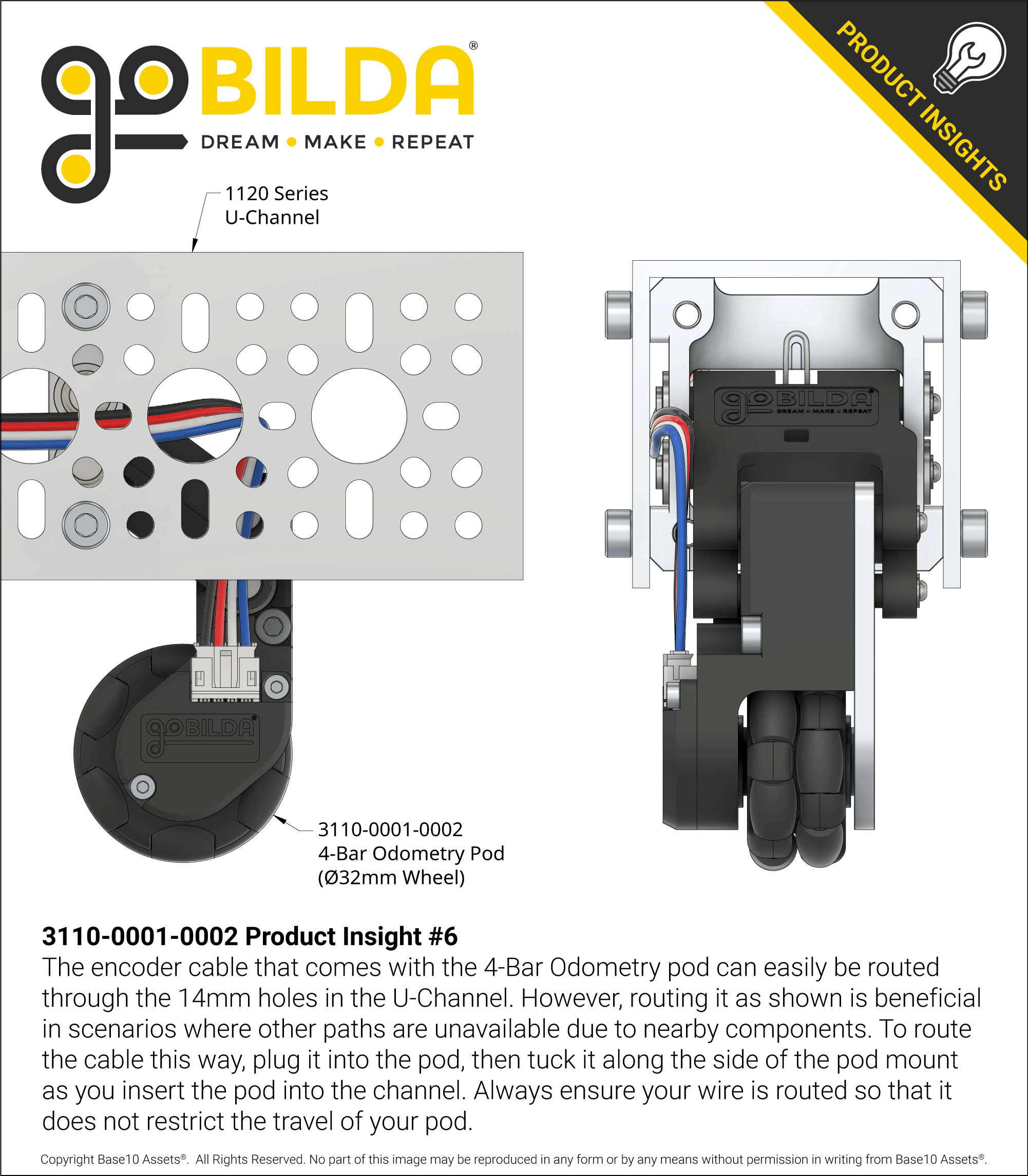

It functions as a “dead” 32mm diameter omni wheel integrated with a 2000 PPR encoder that, when powered via its JST PH connection, outputs the data of the dead wheel’s rotations against the ground as the chassis moves. Since the dead wheel doesn’t rotate otherwise, its rotation—and thus its data output—depends solely on the travel of the chassis.

Equipping an odometry pod to each side of a skid-steer chassis is a perfect way to track the chassis’ overall movement (which is facilitated by the combined input of its two sides). For a chassis with more complex maneuverability, such as a mecanum chassis, a third odometry pod is useful for tracking the additional degree of freedom.

Programming

The other half of odometry is the programming that reads the sensor’s input to derive your robot’s position and generate the path forward. To that end, there are plenty of FTC-focused resources for helping your software team get on-track with odometry! One great FIRST step you can take is this page in Game Manual 0.

Why Odometry Pods?

Many motors (like Yellow Jacket Planetary Gear Motors!) have encoders that output data about their rotation. This can allow your robot to localize based on the rotations of its drive motors. However, your drive wheels may slip if your chassis accelerates too quickly, contacts an object (or another robot), or moves in an unpredictable way. This can cause a build-up of errors that result in your robot veering away from its target.

Fortunately, odometry pods, like the one featured here, allow you to track just the distance traveled instead of how far the motors have turned to get you there.

Tech Terms

Dedicated odometric installations (like this one) often take the form of a "dead" (non-driven) wheel integrated with an encoder sensor as part of a "pod" package that tracks and relays information about the wheel's rotations as it travels against a surface. That's why they’re often known as "odometry pods," "dead wheels," or "tracking wheels.”

Included Components:

| SKU | Qty | Name |

|---|---|---|

| N/A | 1 | 4-Bar Mini Odometry Pod (32mm Wheel) |

| 2800-0004-0006 | 4 | M4 x 0.7mm Zinc-Plated Socket Head Screw (6mm Length) |

| 3804-0707-0600 | 1 | JST PH Extension (4-Pos JST PH, MH-FC to MH-FC, 600mm Length) |

Downloads

Specs

| Weight | 84g (includes wire and mounting hardware) |

|---|---|

| Wheel Material | Plastic with Rubber Rollers |

| Wheel Durometer | 50A |

| Encoder Connector Type | 4-Pos JST PH [FH-MC] |

| Encoder Resolution | 2000 Countable Events per Revolution |

| IP | Patents Pending |