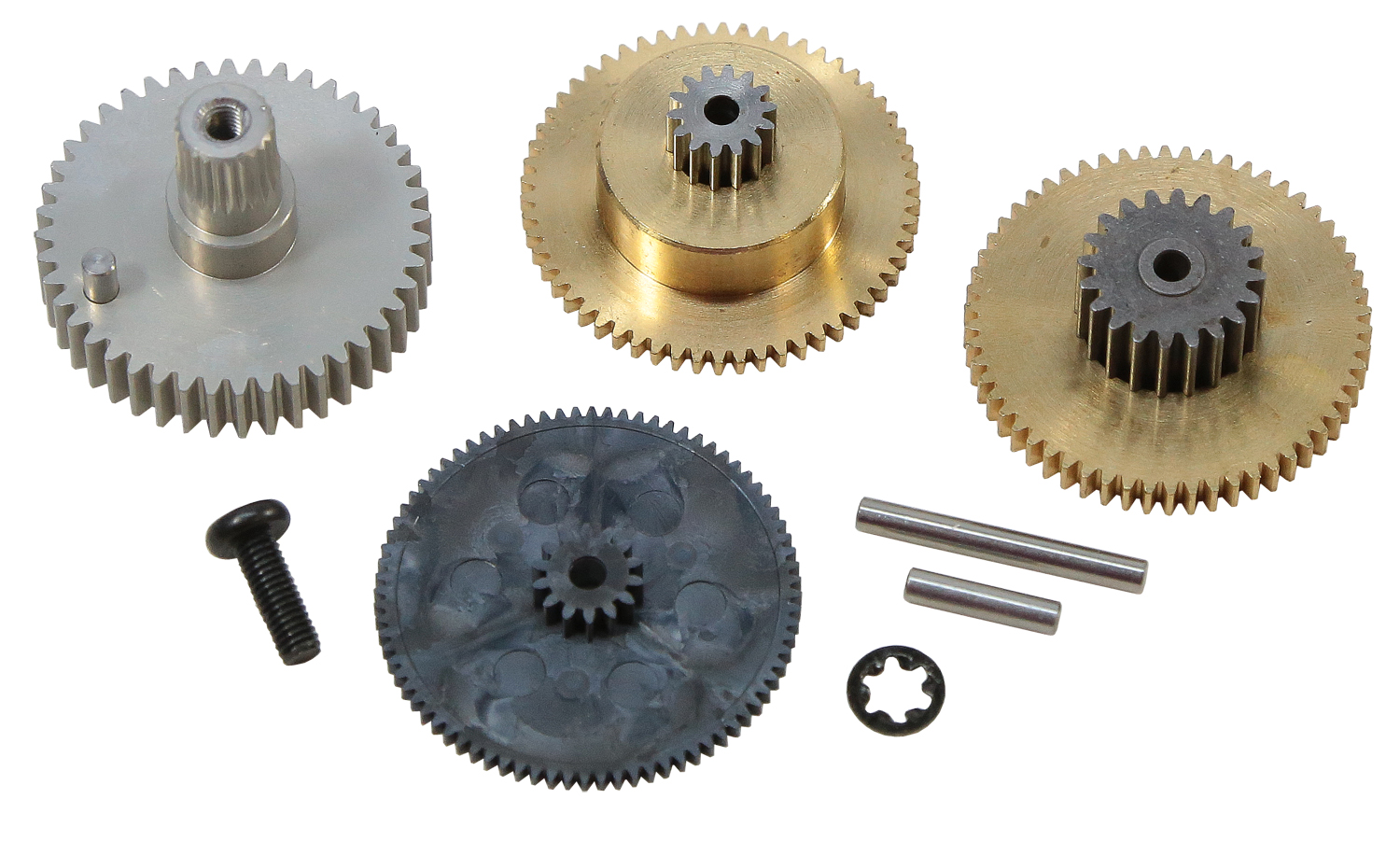

55316 Hitec OEM Replacement Gear Set

SKU:There are two things that you need to know about metal gears in servos. First, they offer much greater strength than their nylon or karbonite counter parts. If your application experiences many jolts and heavy vibration, metal gears are usually the way to go. Second, metal gears wear much faster than their nylon or karbonite counter parts. Although stronger, metal gears will develop a certain amount of play in the gears over time. How much depends on how much load is placed on the servo and the cycle time. If your application needs precision over a period of time we highly recommend using nylon or even better, karbonite gears.

Be sure to grease your replacement gears when you install them.

Note: Nylon geared servos will accept metal gears of their equivalent. Example: HS-81 nylon geared servo will accept HS-81 metal gears.

Specs

| Servo Compatibility | HS-755HB, HS-755MG |

|---|