HSB-9485SH Servo

How Far Will This Servo Rotate?

The answer to this question is partially dependent on what you are using to control the servo.

Click for a quick video explanation.

Stock:

With an Average Radio System:

67°

Your average transmitter and receiver will output a relatively narrow PWM signal range.

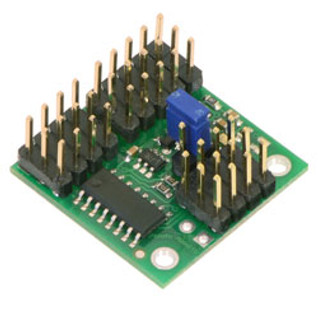

Radio System + Travel Tuner:

120°

Adding a Servo Travel Tuner to your radio system setup will allow you to achieve wide PWM signal ranges.

Wide Signal Controllers:

120°

Controllers such as the Servo Commander, Arduinos, and Raspberry Pi servo hats can usually send a wide signal.

Reprogrammed:

Whether you purchase the reprogrammed option or get a servo programmer and do it yourself, a reprogrammed version of this servo will be able to achieve greater travel than it can in stock form.

With an Average Radio System:

114°

Your average transmitter and receiver will output a relatively narrow PWM signal range.

Radio System + Travel Tuner:

203°

Adding a Servo Travel Tuner to your radio system setup will allow you to achieve wide PWM signal ranges.

Wide Signal Controllers:

203°

Controllers such as the Servo Commander, Arduinos, and Raspberry Pi servo hats can usually send a wide signal.

Special Features

- Constant torque output: Revolutionary circuit and motor designs allow the HSB-9XXX Series servos to maintain their speed in a more consistent manner, regardless of load.

- Hybrid MPD 1st Gear: Unique ultra-durable Metal/Plastic/duralumin hybrid first gear prevents inadvertent electrical noise from affecting other components within your aircraft or vehicle

- Custom NeuMotor: Designed by Steve Neu exclusively for the HSB-9XXX Series, these high performance, brushless motors provide long-standing durability and performance.

Brushless Advantages

- At least FIVE TIMES longer-lasting than brushed servos.

- 30% faster response times.

- Greater resistance to jolts and vibration.

- Smoother operation.

- Same power consumption as brushed digital servos.

- Same compact case size as standard servos.

- Exceptionally durable geartrain.

- Smooth dual ball bearings

PLEASE NOTE

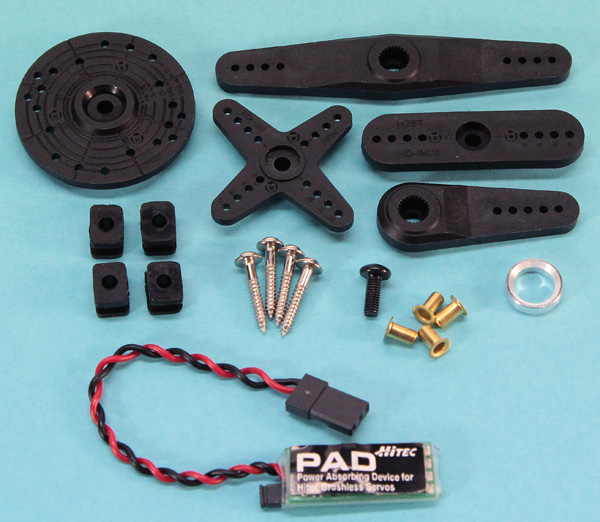

While compatible with most radio control devices, the regenerative braking feature of the HSB-93XX series servos may cause a problem if the device cannot accept a backflow of current. The types of devices that cannot accept this backflow are: Voltage Regulators, Power Safe Receivers and certain BEC circuits whether stand alone or integrated within an Electronic Speed Control. Check with the manufacturer or the Hitec website for a list of compatible models. If your device cannot accept a current backflow, then you must install a PAD (Power Absorbing Device - Hitec PN# 55756) as described in the manual. A PAD is included with every Hitec brushless servo.

Specs

| Output Shaft Style | H25T Spline |

|---|---|

| Voltage Range | 6.0V - 7.4V |

| No-Load Speed (7.4V) | 0.15 sec/60° |

| No-Load Speed (6.0V) | 0.18 sec/60° |

| Stall Torque (6.0V) | 361 oz-in (26 kg.cm) |

| Stall Torque (7.4V) | 361 oz-in (26 kg.cm) |

| Max PWM Signal Range | 700-2300μsec |

| Travel per µs (Stock) | .075°/μsec |

| Max Rotation (Stock) | 120° |

| Pulse Amplitude | 3-5V |

| Operating Temperature | -20°C to +60°C |

| Continuous Rotation Modifiable | No |

| Direction w/ Increasing PWM Signal | Clockwise |

| Deadband Width | 2µs |

| Motor Type | Brushless |

| Feedback Style | 5KΩ Potentiometer |

| Output Shaft Support | Dual Ball Bearings |

| Gear Material | Steel |

| Wire Length | 11.81" (300mm) |

| Weight | 2.19oz (62g) |

| Wire Gauge | 20AWG |

| Servo Size | Standard |

| Max Rotation (Reprogrammed) | 203° |

| Travel per µs (Reprogrammed) | 0.127°/μsec |