HSR-M9382TH Servo

The HSR-M9382TH is the new king of standard size servos! We’ve long awaited a multi-turn servo in a standard size and are giddy about what Hitec has delivered. Check out some of the high-points:

Multi-Turn:

Leading off with the killer feature, it’s multi-turn while retaining position feedback. How many turns, you ask? Up to 7 turns, but as with any servo, the rotation depends on the signal you send to it.

Programmable:

You can plug the servo in and run it with your servo controller without ever having to worry about programming, but keep in mind what’s on tap:

- Rotation: The endpoints can be adjusted to increase (or decrease) the amount of rotation available. The max achievable is 7 turns but you can tailor the rotation to exactly what you need.

- Continuous Mode: If your project requires multi-turns without feedback, toggle to continuous rotation mode and let it spin without bounds in either direction.

- Speed: The speed of the servo can be adjusted. Max speed is the default, but if your project needs a bit slower movements, plug in and dial it down.

- Fail-Safe: This feature is a mere safety net but let’s face it, things happen when relying on electronics. Fail-safe allows you to set a position that the servo will go to in the unfortunate case that there’s a signal loss between the servo controller and the servo.

- Direction: This servo, like any, is bidirectional but if you want to change the direction it moves when increasing (or decreasing) the PWM signal, you can change the direction with the click of a button.

- Deadband Width: This setting refers to the position accuracy of the servo. The smaller the deadband, the finer point the servo is looking for. The default setting is 1, which is the most precise. In some cases, such as when running multiple servos on one channel, a wider deadband is preferred so that the servos can work in unison.

- Soft Start: If you want the ramp-up from idle to max speed to be slightly lessened, you can adjust the Soft Start from 20% (default) up to 100%.

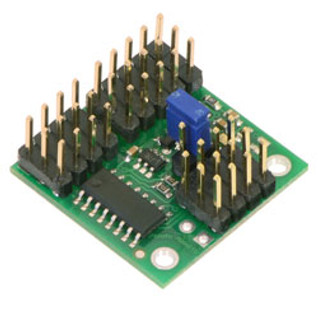

All of the above features can be accessed using the Hitec DPC-11 PC interface servo programmer. The programmer will plug into a PC using a USB to mini USB cable. It requires a 6V battery and the BLDC_HSR User interface_Ver 3.1. You cannot program the servo using the default Ver 2.9 software that the DPC-11 ships with.

For those of you less eager to jump into changing parameters with a servo programmer, we’ve created some popular baseline programs that you’re able to have us pre-load onto the servo; just select the row on the table that best fits your project! The table will give you a general idea of how much rotation you should expect when selecting between the four programming options. Keep in mind, you may get slightly more rotation than we’ve listed as we don’t know the exact PWM range your servo controller is sending so use the table as a general guide.

Brushless Motor: The servo is driven with a Neu Brushless motor. It delivers unparalleled torque and does so while transmitting low levels of audible noise rather than the screeching that some of us have become accustomed to while using digital servos. Hitec’s brushless motors are able to generate large amounts of torque, and for extended periods of time, without building excessive heat like a digital servo with a brushed motor would.

Encoder: Because the servo is multi-turn, an encoder was used in place of a potentiometer. Encoders are non-contact, therefore you don’t have to worry about the resolution degrading over time in heavy-use applications. Note that since the servo is multi-turn, the positioning feedback is relative rather than absolute.

Titanium Gears: To compliment the torque available, the servo boasts titanium gears for ultimate durability!

H25T Spline: Hitec has continued their recent trend by using the H25T spline which has won out as the standard within the R/C industry. Furthermore, they used an M3 screw to hold the horn for greater strength and ease of use.

How Far Will This Servo Rotate?

The answer to this question is partially dependent on what you are using to control the servo.

Click for a quick video explanation.

Stock:

With an Average Radio System:

0.765 Turns (275°)

Your average transmitter and receiver will output a relatively narrow PWM signal range.

Radio System + Travel Tuner:

1.19 Turns

Adding a Servo Travel Tuner to your radio system setup will allow you to achieve wide PWM signal ranges.

Wide Signal Controllers:

1.19 Turns

Controllers such as the Servo Commander, Arduinos, and Raspberry Pi servo hats can usually send a wide signal.

Reprogrammed (1.75 Turn Max):

Whether you purchase the reprogrammed option or get a servo programmer and do it yourself, a reprogrammed version of this servo will be able to achieve greater travel than it can in stock form.

With an Average Radio System:

1.125 Turns

Your average transmitter and receiver will output a relatively narrow PWM signal range.

Radio System + Travel Tuner:

1.75 Turns

Adding a Servo Travel Tuner to your radio system setup will allow you to achieve wide PWM signal ranges.

Wide Signal Controllers:

1.75 Turns

Controllers such as the Servo Commander, Arduinos, and Raspberry Pi servo hats can usually send a wide signal.

Reprogrammed (7 Turn Max):

Whether you purchase the reprogrammed option or get a servo programmer and do it yourself, a reprogrammed version of this servo will be able to achieve greater travel than it can in stock form.

With an Average Radio System:

4.5 Turns

Your average transmitter and receiver will output a relatively narrow PWM signal range.

Radio System + Travel Tuner:

7 Turns

Adding a Servo Travel Tuner to your radio system setup will allow you to achieve wide PWM signal ranges.

Wide Signal Controllers:

7 Turns

Controllers such as the Servo Commander, Arduinos, and Raspberry Pi servo hats can usually send a wide signal.

Downloads

Specs

| Dimensions | 1.58" x 0.79" x 1.50" (40.0mm x 20.0mm x 38.0mm) |

|---|---|

| Weight | 2.4oz (68g) |

| Output Shaft Style | H25T Spline |

| Voltage Range | 6.0V - 7.4V |

| No-Load Speed (6.0V) | 0.17sec/60° |

| No-Load Speed (7.4V) | 0.14sec/60° |

| Stall Torque (6.0V) | 472 oz-in. (34 kg.cm) |

| Stall Torque (7.4V) | 472 oz-in. (34 kg.cm) |

| Pulse Amplitude | 3-5V |

| Continuous Rotation Modifiable | Yes |

| Direction w/ Increasing PWM Signal | Clockwise |

| Deadband Width | 1 µsec |

| Motor Type | Brushless |

| Internal Feedback Style | Relative Encoder |

| Output Shaft Support | Dual Ball Bearing |

| Gear Type | MPD 1st Gear & 3 Titanium / Steel Gears |

| Wire Gauge | 20 AWG |

| IP Rating | IP65 |

| Servo Size | Standard |

| Max PWM Signal Range | 800-2200μsec |

| Travel per µs (Stock) | 0.306°/µsec |

| Travel per µs (Reprogrammed - 1.75 Turn Max) | 0.450°/µsec |

| Travel per µs (Reprogrammed - 7 Turn Max) | 1.800°/µsec |

| No-Load Current | 250mA |

| Stall Current | 2,700mA |